To achieve a smooth and even surface, industrial products undergo polishing using a coating machine before surface spraying. During this process, the workpiece generates large amounts of dust, including metal dust, grinding wheel dust, fiber dust, and waste paint particles. These dust particles not only contaminate the work environment but also pose potential health risks to workers and may affect the quality of the final product. Proper dust extraction and control measures are essential to maintain a clean and safe workplace while ensuring high-quality surface finishing in industrial applications.

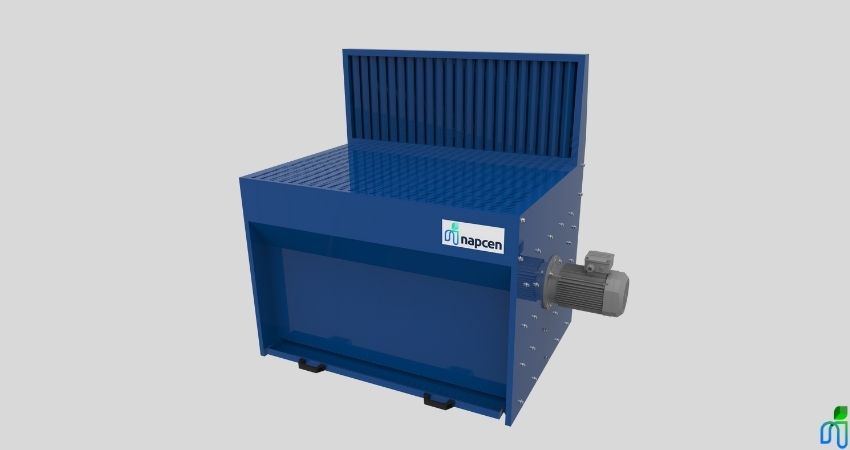

The Downdraft Table for polishing, designed by Napcen, is a system specifically created to capture fumes and dust generated during welding, cutting, grinding, and polishing. This table is capable of handling various workpieces, including small and lightweight parts, making it highly versatile and portable. The independent and easily movable design allows for convenient relocation. Working with the downdraft table significantly reduces harmful gases in the environment, protecting staff from exposure and ensuring a safer, cleaner workplace. This system is an effective solution for maintaining air quality and enhancing worker safety in industrial settings.

Welding, Grinding, Sanding etc...

Abrasive/ Sticky/ Explosive, Concentration in ppm or kg/hr

The operation will be 24 x 7 or 8 hrs shift

Mension the process area (LXWH)